VMC850B CNC Milling muchina, vertical muchina pakati

Product Features

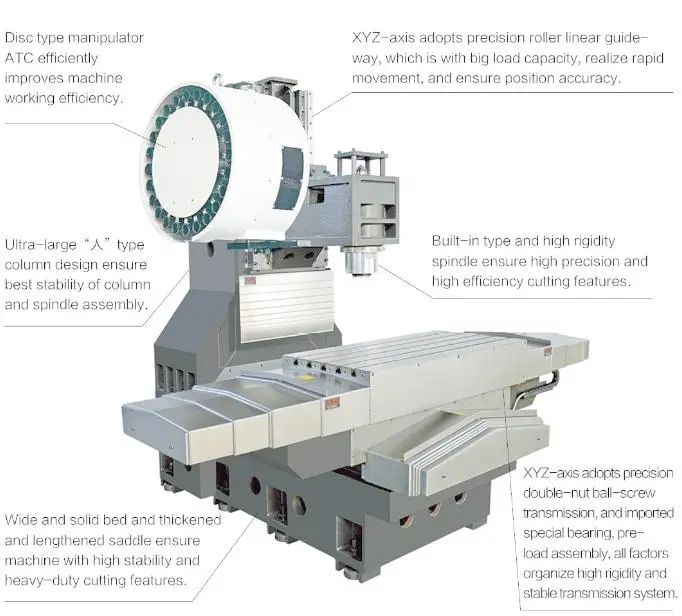

1.Overall rairo

Muchina uyu wakagadzirwa une vertical furemu marongero. Iyo column yakaiswa pamuchina wemuchina, spindle bhokisi inotsvedza pambiru inogadzira Z axis kufamba, masadhi masiraidhi pamushini wemuchina uchigadzira Y axis motion, Worktable masiraidhi pasadhi achigadzira X axis kufamba. Matemo matatu ese ane mutsara gwara rine kukurumidza kudyisa uye nepamusoro nemazvo. Isu tinoshandisa yemhando yepamusoro grey cast iron yemuchina wemuchina, mbiru, chigaro, tafura yekushanda, spindle bhokisi ine resin jecha tekinoroji uye kaviri kurapwa kuchembera kubvisa mukati kusara kunetseka kwezvinhu. Zvikamu izvi zvese zvakagadziridzwa neSolidWorks software, iyo inovandudza kuomarara uye kugadzikana kwete zvezvikamu izvi chete asi muchina. Uyewo inodzivisa deformation uye vibration inokonzerwa nekucheka. Izvo zvakakosha zvikamu zvese zvinounzwa kubva kune yakakurumbira brand brand kugadzira muchina wacho nekugadzikana kwepamusoro uye kusimba. Muchina uyu unogona kuzadzisa maitiro ekugaya, kudhirowa, kudzoreredza, kufinha, kugadzirazve, kubata uye kazhinji kushandiswa kuMasoja, migodhi, mota, mold, instrumentation uye mamwe maindasitiri ekugadzira michina. Inogona kushandiswa kune ese marudzi emhando yepamusoro uye yakawanda maitiro emhando. Yakanakira diki uye yepakati-saizi, yakawanda-yakasiyana kugadzirwa, zvakare inogona kuisa mune otomatiki yekugadzira mutsara.

2.Three axes system

Matemo matatu ese ane mutsara gwara uye ane hombe span dhizaini yekusimba kwakasimba. Iwo mota dzemasanhu matatu akabatana zvakananga nepamusoro chaiyo bhora screw pasina gap flexible coupling. Rimwe nerimwe bhora sikuruu remasanhu matatu rinounzwa kubva kune chaiyo angular yakabatwa bhora sikuruu uye nyanzvi mabearings akafananidzwa, zvakare tichaita pre-tension yebhora masiruu for accuracy epamusoro uye nemazvo.Iyo Z-axis servo motor ine automatic brake function. Panyaya yekutadza kwemagetsi, mota brake inogona kubatwa otomatiki nebhureki kuti irege kutenderera, iyo inoita basa rekuchengetedza kuchengetedza.

3.Spindle unit

Spindle inogadzirwa nemugadziri wehunyanzvi kuti ave nechokwadi chepamusoro uye kusimba. Spindle bearing inobva pasi rose yakakurumbira high precision bearing brand, uye yakaungana pamamiriro ekugara tembiricha uye pasina guruva. Mushure meizvozvo, maspindle ese achaita bvunzo yesimba rekuita kuti ive nechokwadi chekuti hupenyu hurefu uye kuvimbika. Iyo yakashongedzerwa ine low pressure air cycle protection system, ichifuridza yakaderera mhepo mukati mespindle yemukati nzvimbo ichigadzira mhepo yekudzivirira layer kudzivirira guruva, kutonhora mukati. chokurunga. Kune iyi mamiriro, iyo spindle inotakura ichashanda pasina kusvibiswa nharaunda, iyo inodzivirira iyo spindle unit uye nehurefu hwehurefu hwehupenyu. Spindle kumhanya inogona kunge isina-nhanho yakashandurwa mukati meiyo spindle yekumhanyisa renji, iyo inodzorwa nemotor yemukati encode kuti ive nebasa rekutenderera kwespindle uye kuomarara tapping.

4.Tool shanduko yehurongwa

Iyo yakajairwa dhizaini rekushandisa remuchina uyu ndeye 24T uye yakaungana padivi pembiru. Kana ichichinja chishandiso, dhiraivha ndiro dhiraivha uye nekumisikidzwa nemotor drive hobbing cam mechanism, mushure mekunge spindle yasvika pachinzvimbo chekuchinja kwechishandiso, iyo ATC inowana shanduko yekushandisa uye kutumira chishandiso chiito. ATC iri hobbing cam mechanism uye inoita pre-tension ipapo inogona kumhanyisa kutenderera, izvo zviri nani kukurumidza uye kwakaringana shanduko yekushandisa.

5.Coolant system

Muchina uyu wakashongedzerwa nehombe inoyerera yakatwasuka yekunyudza yekutonhodza pombi uye hombe yemvura tangi. Iko kumhanya kwepombi yekutonhodza i2m³/h kuve nechokwadi chekudzoreredza kutonhora kwakaringana. Pane inotonhodza nozzle pane spindle box end surface, iyo inogona kuita kuti mhepo inotonhoresa uye inotonhodza mvura yechishandiso nezvimedu zvebasa. Akashongedzerwa nemhepo pfuti kuchenesa muchina uye basa zvidimbu.

6.Pneumatic system

Pneumatic unit inogona kusefa kusvibiswa uye hunyoro mune gasi sosi kudzivirira kukuvadzwa uye kukukurwa kwezvikamu zvemuchina. Solenoid valve unit inodzora chirongwa nePLC kuti ive nechokwadi chekuti zviito zve spindle unclamping chishandiso, spindle centre inovhuvhuta, spindle clamping chishandiso uye spindle mhepo inotonhorera inogona kugadzirwa nekukurumidza uye nemazvo. Pese pese pese pese pese pese pese pese pese pese, mweya wakadzvinyirirwa unovhuvhuta uchibva panzvimbo yespindle kuti uchenese gomba remukati remupindo uye shank yechishandiso kuitira kuomarara kwemusanganiswa nespindle nechishandiso. Ichawedzera hupenyu hwema spindle.

7.Muchina kudzivirira

Isu tinoshandisa yakajairwa kuchengetedza nhovo yemuchina, iyo isingango chengetedza inotonhorera splash asi kuchengetedza kushanda. Yese gwara rakashongedzerwa nenhoo yekudzivirira kudzivirira inotonhorera uye yekucheka chidimbu mukati memukati uye kuderedza kupfeka uye kukukurwa kwegwara uye bhora screw.

8.Lubrication system

Guideway uye bhora screw yakashongedzerwa nepakati lubrication system uye ine volumetric mafuta separator mune Imwe neimwe node, iyo inogona kupa oiri pahuwandu hwakatarwa uye nguva kuve nechokwadi chega chega chinotsvedza chiso chakazorwa uye chakaderera kugadzirwa. Ichavandudza huroyi uye hurefu hwehupenyu hwebhora screw uye gwara.

9.Chip conveyor system

Isu tinopa yakajairika manual chip remover mudziyo nekushanda kuri nyore. Zvakare iwe unogona kusarudza screw type chip conveyor kana hinge mhando.

| Item | Unit | VMC640L | VMC640LH | VMC850L | VMC1000L |

| Worktable | |||||

| Worktable size | mm | 400×900 | 400×900 | 500 × 1000 | 500 × 1200 |

| T-slot (N×W×D) | mm | 3×18×100 | 3×18×100 | 5 × 18 × 100 | 5 × 18 × 100 |

| Travel | |||||

| X axis kufamba | mm | 640 | 640 | 850 | 1000 |

| Y axis kufamba | mm | 400 | 400 | 500 | 500 |

| Z axis kufamba | mm | 400 | 500 | 600 | 600 |

| Machining range | |||||

| Distance from spindle center to column kumberi | mm | 440 | 476 | 572 | 572 |

| Distance from spindle end to work table | mm | 120-520 | 120-620 | 120-720 | 120-720 |

| Machine dimension | |||||

| L×W×H | mm | 2200×2100×2500 | 2200×2100×2550 | 2540×2320×2780 | 3080×2320×2780 |

| Machine uremu | |||||

| Max. kutakura mutoro wetabhenakeri | kg | 350 | 350 | 500 | 600 |

| Machine uremu | kg | 3900 | 4100 | 5200 | 5600 |

| Spindle | |||||

| Spindle gole taper | BT40 | BT40 | BT40 | BT40 | |

| Spindle simba | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Max. spindle speed | rpm | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Kudyisa (direct drive) | |||||

| Max. feed speed | Mm/min | 10000 | 12000 | 12000 | 12000 |

| Kukurumidza kudyisa kumhanya (X/Y/Z) | m/min | 20/20/10 | 30/30/24 | 32/32/30 | 32/32/30 |

| Bhora screw (diameter + lead) | |||||

| X axis bhora sikuruu | 3210 | 3212 | 4016 | 4016 | |

| Y axis ball screw | 3210 | 3212 | 4016 | 4016 | |

| Z axis bhora sikuruu | 3210 | 4012 | 4016 | 4016 | |

| Tool Magazine | |||||

| Tool magazini kukwanisa | T | 16 | 16 | 24 | 24 |

| Tool kuchinja nguva | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Positioning kurongeka (National standard) | |||||

| Kumira kwechokwadi (X/Y/Z) | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Kurongekazve kwechokwadi(X/Y/Z) | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| AIHWA. | Zita | Brand |

| 1 | CNC system | Seimens 808D SYSTEM |

| 2 | Main mota | Seti yakazara yeSiemens drive inosanganisira servo mota |

| 3 | X/Y/Z axis mota, mutyairi | Seimens |

| 4 | Ballscrew | Hiwin kana PMI (Taiwan) |

| 5 | Ballscrew bearing | NSK (Japan) |

| 6 | Linear guides | Hiwin kana PMI (Taiwan) |

| 7 | Spindle motor | POSA/ROYAL (Taiwan) |

| 8 | Heat exchanger | Taipin/Tongfei (Joint-venture) |

| 9 | Lubrication system main components | Proton (Joint venture) |

| 10 | Pneumatic system main components | AirTAC (Taiwan) |

| 11 | Electric system main components | Schneider (France) |

| 12 | Pombi yemvura | China |